// Old Switcher-hidden

Resources

-

Array, Array

-

As CNC parts often need secondary services, we work with a routinely audited list of proven suppliers for:

- Anodizing (Soft & Hard, Types II and III)

- Bead Blasting

- Titanium Anodizing

- Passiation

- Chemical Film

- PTFE Impregnated

- Plating

- Nickel Plating

- Copper Plating

- Black Oxide

- Electropolishing

- Chromate

- Tumbling

- Conversion Coating

- Powder Coating

- Electroless Nickel

- Silver Plating

- Gold Plating

- Zinc Plating

- Tin Plating

- Lead Plating

- Rhodium Plating

- Palladium-Nickel Plating

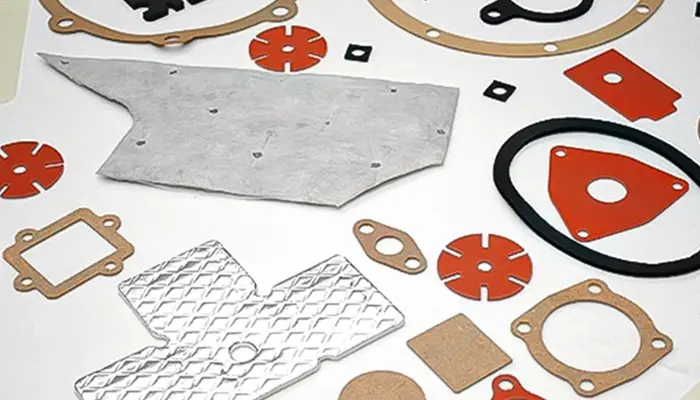

Post Processes

As CNC parts often need secondary services, we work with a routinely audited list of proven suppliers for:

- Anodizing (Soft & Hard, Types II and III)

- Bead Blasting

- Titanium Anodizing

- Passiation

- Chemical Film

- PTFE Impregnated

- Plating

- Nickel Plating

- Copper Plating

- Black Oxide

- Electropolishing

- Chromate

- Tumbling

- Conversion Coating

- Powder Coating

- Electroless Nickel

- Silver Plating

- Gold Plating

- Zinc Plating

- Tin Plating

- Lead Plating

- Rhodium Plating

- Palladium-Nickel Plating

Technical Info

Milled Parts

Tolerances as tight as +.0005” can be achieved. Without a supplied drawing, Additive Manufacturing LLC will quote to achieve a .005” tolerance throughout. Part thickness for milled parts should be designed thicker than .020” in all areas. Radii is typically rounded since sharp corners are difficult to achieve with the machining process. Text in plastics, aluminum, copper and bronze should be designed with a minimum width of 0.018” and a depth of 0.012”Text in steel and other hard metals should be designed with a minimum width of 0.033” and a depth of 0.012”Recessed text is much easier to achieve than raised text due to the nature of subtractive manufacturingThe largest single-piece size we can manufacture is 120” x 55”Sharp edges are deburred

Tolerances as tight as +.0005” can be achieved. Without a supplied drawing, Additive Manufacturing LLC will quote to achieve a .005” tolerance throughout. Part thickness for milled parts should be designed thicker than .020” in all areas. Radii is typically rounded since sharp corners are difficult to achieve with the machining process. Text in plastics, aluminum, copper and bronze should be designed with a minimum width of 0.018” and a depth of 0.012”Text in steel and other hard metals should be designed with a minimum width of 0.033” and a depth of 0.012”Recessed text is much easier to achieve than raised text due to the nature of subtractive manufacturingThe largest single-piece size we can manufacture is 120” x 55”Sharp edges are deburred

Turned Parts

Tolerances as tight as + .0002” can be achieved. Without a supplied drawing, Additive Manufacturing LLC will quote to achieve a .005” tolerance throughout.Minimum wall thickness is 0.020”Angles should be designed greater than .030”Finished-part surface quality is much finer with turned parts than with milled parts.

Tolerances as tight as + .0002” can be achieved. Without a supplied drawing, Additive Manufacturing LLC will quote to achieve a .005” tolerance throughout.Minimum wall thickness is 0.020”Angles should be designed greater than .030”Finished-part surface quality is much finer with turned parts than with milled parts.

Materials

Materials - Metal

- Aluminum (all grades)

- Brass

- Bronze

- Cobalt Chrome

- Copper (all grades)

- Inconel (all grades)

- Low Carbon Steel (all grades)

- Stainless Steel (all grades)

- Steel Alloy

- Titanium (all grades)

- Zinc

- Any custom alloy

Materials – Plastic

- ABS

- Acrylic

- Delrin (Acetal)

- G-10 FR4

- Garolite

- HDPE

- Nylon 6/6

- PC (Polycarboate)

- PTFE (Teflon)

- UHMW PE

- PVC

- Ultem

- Any custom plastic

Get in Touch with Us

Reach Out for Inquiries, Assistance, and More

Please contact us if you have any questions, comments or require

Need a Quote?

Features of our quoting system

Upload Files Directly

Just simply create an account, and upload your 3D files.

24 Hour Access

It can be hard to get things done over the phone, just use our system any time of day.

Digital Quotes

Upload your files, and we will send you a personalized quote.

Experienced Manufacturers

You can trust the brand Additive Manufacturing LLC

Best Prices

We offer competitive pricing to any client, small or large.

Register for your quote