Resources

-

Tech Sheets

-

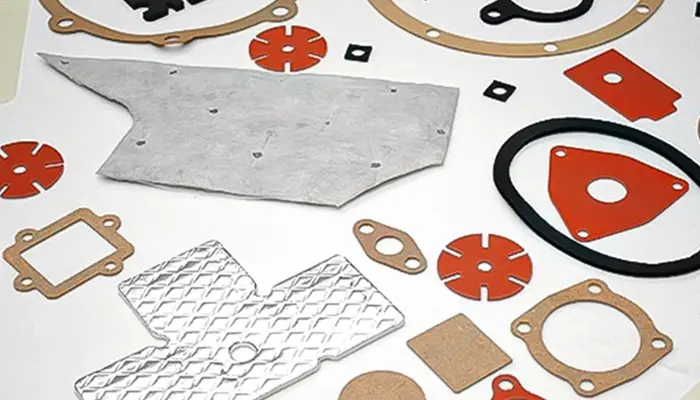

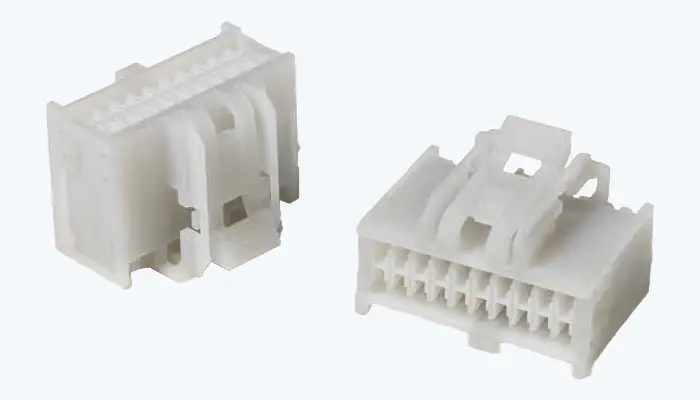

There are a large variety of secondary services that can and in some cases should be performed depending on the alloy being printed.

For Surfaces:

- Finish CNC (3- and 5-axis milling)

- Turning

- Wire EDM

- Polishing

- Plating

- Passivation

- Anodizing

- Tapping and Reaming

- Hardware Installation

- Powder Coating

- Assembly

For Heat Treatments:

- Hot Isostatic Pressing (HIP)

- Solution Annealing

- Aging

- Stress Relieving

- NADCAP

For Powder Analysis:

- Chemistry

- Particle Size Analysis

- Traceability

For Testing:

- Tensile Bar Pull

- Rockwell Hardness

- X-Ray

- Stress Testing

Post Processes

There are a large variety of secondary services that can and in some cases should be performed depending on the alloy being printed.

For Surfaces:

- Finish CNC (3- and 5-axis milling)

- Turning

- Wire EDM

- Polishing

- Plating

- Passivation

- Anodizing

- Tapping and Reaming

- Hardware Installation

- Powder Coating

- Assembly

For Heat Treatments:

- Hot Isostatic Pressing (HIP)

- Solution Annealing

- Aging

- Stress Relieving

- NADCAP

For Powder Analysis:

- Chemistry

- Particle Size Analysis

- Traceability

For Testing:

- Tensile Bar Pull

- Rockwell Hardness

- X-Ray

- Stress Testing

Technical Info

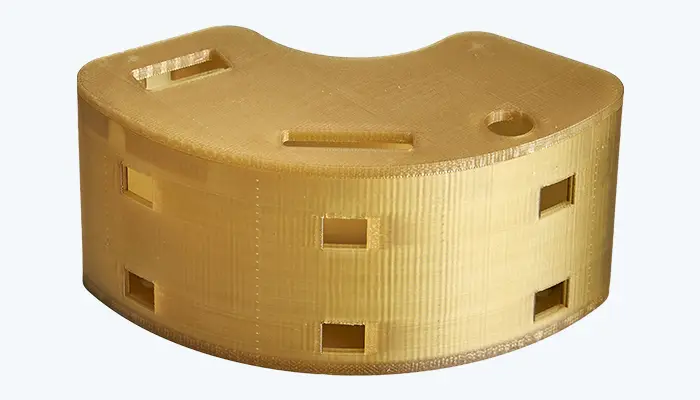

Tolerances for as-printed parts are + 0.010” throughout

Wall thickness should be designed at 0.030” (supported)

Wall thickness should be designed at 0.039” (unsupported)

Minimum feature size 0.015” but 0.020” is optimal

Minimum hole size is 0.030” and in some cases can be as thin as 0.022”

Lettering should be designed at 0.19” tall or deep with a minimum font size of 14

Fillets are valuable in that they reduce stress which tends to occur with DMLS metal 3D printing

Improved tolerances can be achieved by adding approximately 0.045” worth of stock to all areas where finish CNC is desired. Finish CNC can achieve improved tolerances of + 0.0005”

Tech Sheets

Get in Touch with Us

Reach Out for Inquiries, Assistance, and More

Please contact us if you have any questions, comments or require

Need a Quote?

Features of our quoting system

Upload Files Directly

Just simply create an account, and upload your 3D files.

24 Hour Access

It can be hard to get things done over the phone, just use our system any time of day.

Digital Quotes

Upload your files, and we will send you a personalized quote.

Experienced Manufacturers

You can trust the brand Additive Manufacturing LLC

Best Prices

We offer competitive pricing to any client, small or large.

Register for your quote