Resources

-

Array, Array

-

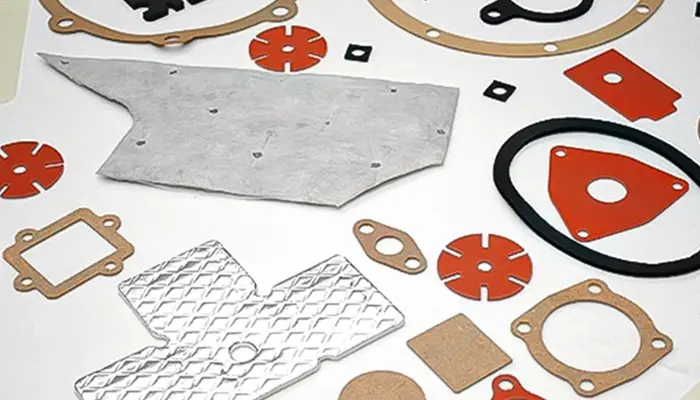

A variety of finishing options are offered for sheet metal parts.

- Plating

- Powder Coating

- Riveting

- PEM Hardware Installation

- TIG and MIG Welding

- Silk Screening

- Laser Etching

- Laser Engraving

- Assembly

Post Processes

A variety of finishing options are offered for sheet metal parts.

- Plating

- Powder Coating

- Riveting

- PEM Hardware Installation

- TIG and MIG Welding

- Silk Screening

- Laser Etching

- Laser Engraving

- Assembly

Technical Info

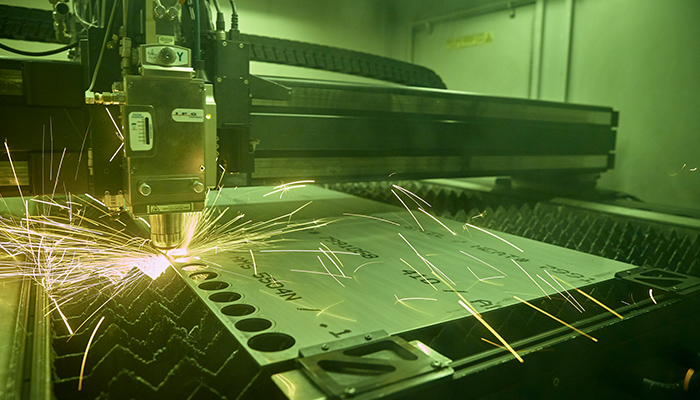

Laser Cutting is the most widely used process for cutting the flat sheets of metal. Depending on the laser type, tolerances that range from + 0.0005” to + 0.002” can be achieved. Aluminum, copper, brass, steel and stainless steel are the most widely laser cut used materials.

Laser Cutting

6000 watt DNE Fiber Laser machines

Tolerance accuracy ranges from + 0.0005” to + 0.002”

Maximum Single-piece size is 60” x 120”

Multiple manufacturable gauges130 watt CO2 Laser (Sealed off) with pass-through system

Tolerance accuracy ranges from + 0.0005” to + 0.002”

Maximum single-piece size is 24” x 39”

Multiple manufacturable gaugesPress Break Forming requires specialized machinery and tools to create curves and sharp corners, and is the most commonly used forming process to change flat metal parts into more unique shapes. We can perform various types of forming to create custom parts.

Minimum size flat for forming 0.03” x 0.03”

Maximum pressure force 100 tons

+ 1 degree bend angle tolerance

Bend angles 1 to 180 degrees

Open and closed hems are available for all sizes

Waterjet Cutting

Maximum single-piece size is 13.1’ x 6.6’

Complete protection against water, dirt and grit

600 pound bulk abrasive delivery system

For parts less than one inch thick, tolerances range from + 0.002 – 0.005. For shapes thicker than one inch, tolerances range from + 0.005 – 0.010”

Materials

Laser Jet

- Aluminum

- Brass

- Copper

- Titanium

- Low Carbon Steel CR

- CR Galvanized

- CR Galvannealed

- Stainless Steel

- Plastics

- Wood

- Rubber

- Glass

- Foam

Water Jet

- Metal alloys of all types

- Glass

- Ceramic

- Composite

- Plastic

Get in Touch with Us

Reach Out for Inquiries, Assistance, and More

Please contact us if you have any questions, comments or require

Need a Quote?

Features of our quoting system

Upload Files Directly

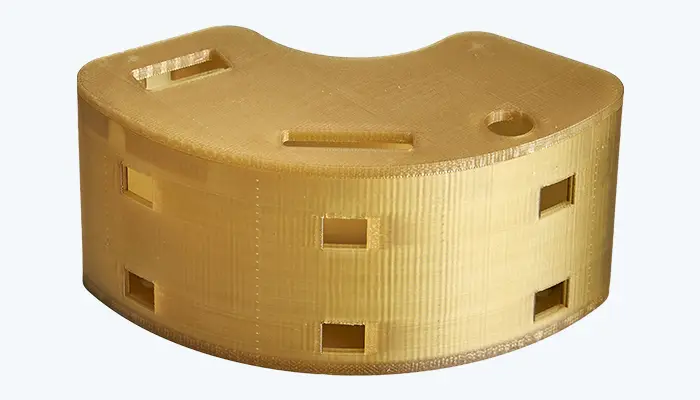

Just simply create an account, and upload your 3D files.

24 Hour Access

It can be hard to get things done over the phone, just use our system any time of day.

Digital Quotes

Upload your files, and we will send you a personalized quote.

Experienced Manufacturers

You can trust the brand Additive Manufacturing LLC

Best Prices

We offer competitive pricing to any client, small or large.

Register for your quote